This course has two major areas of content. First, it is designed to develop students’ ability to interpret needed information, symbols, abbreviations, and conventions contained on industrial blueprints. An overview of reading the blueprint as well as its views, dimensions, tolerances and finishing marks will be stressed. Assembly and detailed drawings will be examined on an advanced level. Geometric dimensions, tolerances, and symbols will also be covered. The second part of the course will be an emphasis on hand drafting. The course offers the opportunity to examine the use of graphics standards and various scales used in technical drawings and to visualize and interpret plan views, sections, and details in prints generated manually. 2 lecture hours, 2 laboratory hours.

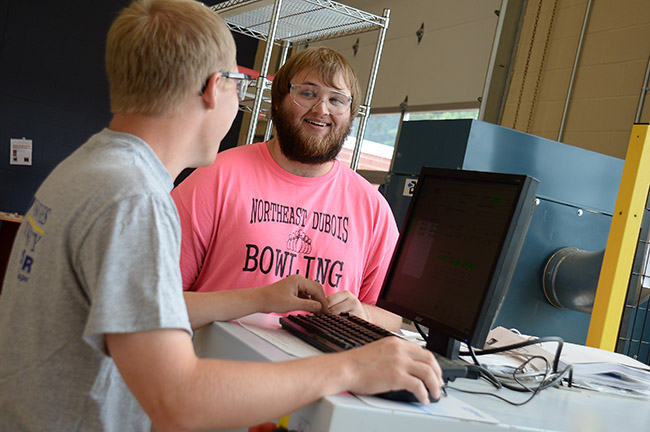

CAP - Career Advancement Partnership - Jasper Campus

mission

Card Title

how to apply to the cap program

Complete the Vincennes University Jasper application process.

Complete the CAP application.

Meet with the Director of the CAP program to determine the next steps.

Participate in Internship interview events

*Note: you must complete both applications.

Electronics Technology - General Technology Concentration 8365, A.S. Career/Tech

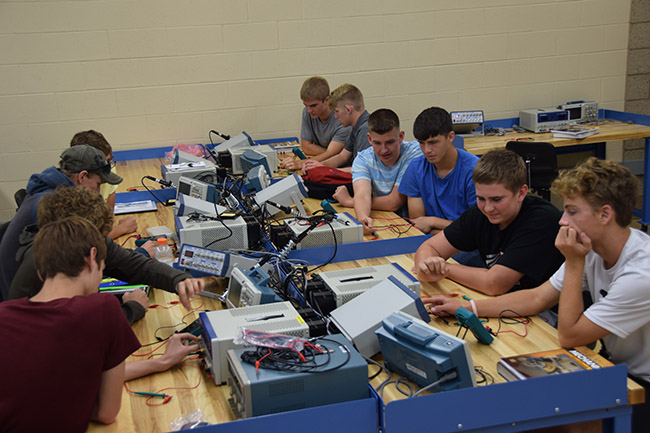

An introductory course in the theory, characteristics, and application of basic electronic components used in AC, DC and digital electronic circuits. Topics will include circuit analysis, measurements, and troubleshooting. Students will study principles of electricity and electronics, participate in Manufacturing Core Exercises (MCE) including safety, 5S, Problem Solving and Maintenance Reliability. 3 lecture hours. Corequisite(s): CIMT 110L.

This course emphasizes the building, analyzing, and troubleshooting of AC, DC, and Digital electronic circuits. 6 laboratory hours. Corequisite(s): CIMT 110.

In this course, each student will program, setup, and operate CNC machinery. All parts will be programmed utilizing one of two methods; Manual G & M code programming or emulation programming software. Emphasis will be placed on process planning, programming efficiency, accurate setup, proper cutter selection, speeds and feeds, carbide tooling, and the generation and interpretation of CNC code for general industry. 1 lecture hour, 6 laboratory hours.

An introductory course in various manufacturing processes for Advanced Manufacturing. Provides training to safely operate commonly used machines such as CNC, Laser, 3-D printing, pneumatic and various other manufacturing equipment. Students will also learn basic machining procedures such as calculating speeds and feeds as well as selecting proper tooling. Several non-traditional machining processes, joining processes and plastic process are also explained. 1 lecture hours, 4 laboratory hours.

A study of the operation, application, and maintenance of the following mechanical components: gears, pulleys, sprockets, chains, bearings, belts, couplings, clutches, and brakes. Other topics include lubrication, alignment, troubleshooting, measurements, tools, hardware, materials, drawings, dimensions, and drive ratios. 2 lecture hours. Corequisite(s): CIMT 140L.

This course emphasizes the setup, alignment, and measurement of single and multi-shaft drive systems using sprockets, pulleys, and gears. 3 laboratory hours. Corequisite(s): CIMT 140.

Conventional techniques in oxy-acetylene and stick-electrode will be covered. Extensive practice will be given for the successful completion of the various required welds. 1 lecture hour, 3 laboratory hours.

This course introduces basic plumbing tools, materials, and fixtures. Topics include standard tools, materials, and fixtures used in basic plumbing systems and other related topics. Upon completion, students should be able to demonstrate an understanding of a basic plumbing system. Troubleshooting techniques for heat pumps, air conditioning and refrigeration systems. 2 lecture hours, 4 laboratory hours.

Introduction to the theory and operation of fluid power systems. This course will cover fluid power components, circuit diagrams, circuit operation, basic fluid power principles,and properties. 1 lecture hour, 2 laboratory hours.

This course covers the operation and programming of a programmable logic controller (PLC). Laboratory experiences include creating ladder logic programs and using them to troubleshoot automation equipment. 1 lecture hour, 2 laboratory hours. Prerequisite(s): Grade of C or better in CIMT 110 and CIMT 110L .

Introduces computer aided drafting (CAD) using latest AutoDesk Inventor program, AutoCAD, 2-D and 3-D software. Students develop skills in drawing set-up and organization, drawing and editing objects, creating complex shapes, dimensioning, using text, display and layer control, using symbols and plotting. Developing CAD models, executing 3D printers from CAD and creating drawings are also included in this course. No previous computer experience is required, but a background in fundamental blueprint and/or drafting skills is recommended. 1 lecture hours, 4 laboratory hours.

This course covers an introduction to Computer Integrated Manufacturing in industry. Programming concepts are introduced using Visual Basic. Emphasis is placed on robotic workcell basics; including programming a robot. Various topics cover robotic classifications, applications, socioeconomic impact, workcell design, robot programming, sensor and actuator interfacing, plus a project centered on a CIM Workcell. 1 lecture, 4 laboratory hours.

Teams of students will be assigned an automation technology project approved by the instructor. The project content will represent several areas of study from courses in the program including computer-aided drafting, application of basic AC/DC electronic components and digital circuits, programming for computer integrated manufacturing, fluid power systems, programming of a programmable logic controller (PLC), and include the use of appropriate project management tasks. 4 laboratory hours. Prerequisite(s): A grade of C or better in DRAF 211, CIMT 110, CIMT 110L, CIMT 201, CIMT 202, and CIMT 220.

Card Title

Contact Information

Jacob Berg, CTIM Director

812-482-3177

jberg@vinu.edu

Karen Mundy, Admissions

812-481-5906

kmundy@vinu.edu